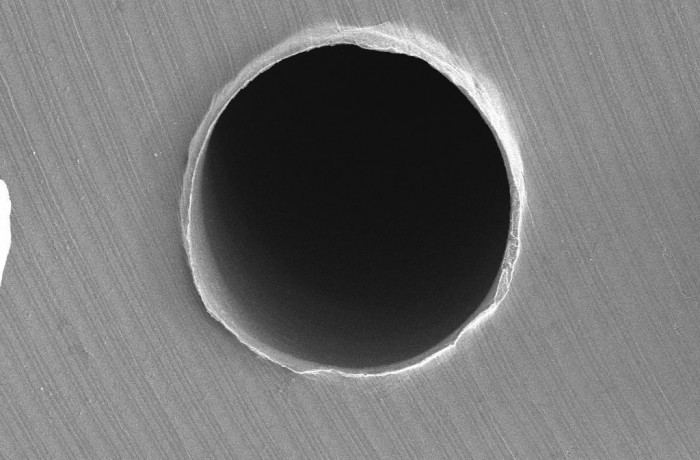

For a particular customer we needed to check the quality of the hole they have drilled. The holes needed to be perfectly round shaped with a diameter of 100 μm. The hole should be a perfect tube with very smooth sidewalls. Besides that the tube should be drilled at a 30º angle with respect to the surface. Several drilling paramaters have been tested, and SEM imaging have determined the best setting for their process.

During SEM inspection we have looked at the holes from both sides and under several angles to determine at which angle it has been drilled.