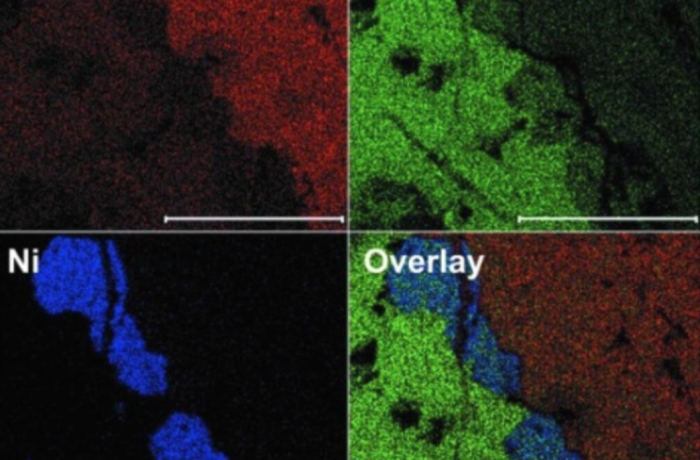

Each company that produces something or is active in development will sooner or later face the question: “Is this material really what it is supposed to be?” or "Does it contain what it should contain?”. You can for instance think of a surface were an adhesive layer does not adhere well. The surface is visually clean, but is this really true? Maybe the surface is oxidized? In case a coating should adhere to nickel (Ni) you would have a real problem when it turns out to be nickel oxide (NiOx). This is optically not visible and can only be demonstrated with material analysis techniques such as EDX, XRF or ToF-SIMS.

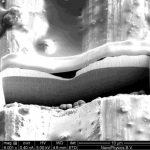

Another example is plating of an electrical contact. Manufactures have to make sure their product is according specification. An electrical contact with purpose in toys or consumer electronics does not require the same specification as connection meant for industry or military purposes. We can assure you there are a lot of doubtfull products on the market. A simple FIB cross section which it nothing more than a 10 x 10μm hole in the surface can reveal if the plating thickness are according specification.